Learn about studs, rough openings and more in traditional platform-frame exterior walls — and why thermal efficiency might not be a priority

Posted from Houzz

Houzz Contributor. My name is Bud Dietrich and I am an architect located in the Tampa Bay area of Florida. I am licensed to practice architecture in Illinois, Florida, New Jersey & Wisconsin and I am a certificate holder from the National Council of Architectural Registration Boards (NCARB). Since 1996 I have worked from my home office and provide full architectural services exclusively to the single family residential market. My passion is to transform my clients' houses into their homes.

Two of the biggest developments of the industrial revolution were the mass production of dimensional lumber for framing, and the nail. Not only did these two products allow for homes to be built by the thousands, but they contributed to a uniquely American style of architecture. Houses were built of smaller, lighter sticks, rather than heavy timbers or masonry.

In the early 19th century, with the onset of stick-built homes, balloon framing became the norm. With this type of framing, the exterior walls are built of continuous wood studs that start at the foundation's sill plate and stop at the highest top plate. The wood studs that make up these walls can therefore easily be 18 or more feet in length. Balloon framing died out simply because of the unavailability of wood studs of such long lengths.

What came about is platform framing, the method used to build wood-frame houses today. It relies on each story of a house being built as a platform so that the exterior walls are built of wood studs no more than about 10 or 12 feet long.

Here's a look at a basic and traditional platform-frame exterior wall, as well as a variant of this system that uses far less material.

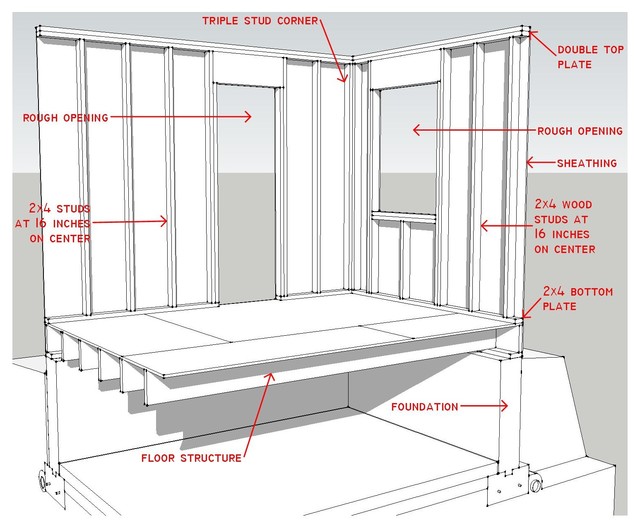

Basic 2-by-4 framing. The most common method of building a wood-frame exterior wall is to use 2-by-4 wood studs spaced 16 inches from the center of one stud to the center of another. These studs are then fastened to a 2-by-4 bottom plate and a double 2-by-4 top plate. Corners have three studs so that there's always a surface to fasten the next material (drywall, sheathing etc.) onto.

Wood-frame walls such as these can be easily built on the wood floor deck and then tilted into place. Once tilted into place and made plumb (straight up and down), even and square (the corners are at 90 degrees or another angle, depending on the design), these walls are securely fastened to the floor structure. Other than the framing needed for openings, such as for doors and windows, the final structural element of a wood-frame wall is the exterior sheathing. Sheathing, usually OSB (oriented strand board) or plywood, is used in most homes to help make the structure rigid so the house doesn't twist or rack. This type of sheathing also provides a surface that siding can be attached to. There are other materials, such as rigid insulation, that can be used in lieu of OSB or plywood. When these materials, which will increase energy efficiency, are used, structural rigidity will be accomplished through bracing or special fasteners or other. |

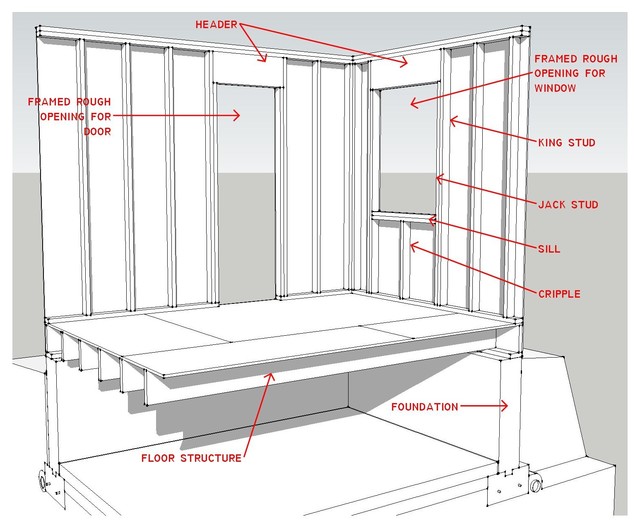

Openings for doors and windows. To accommodate doors and windows, the framings of walls have framed rough openings. In fact, most manufacturers produce windows and doors that fit within a specific rough opening. Knowing the exact window and manufacturer is important in the planning stage so that the carpenters build the walls as needed.

The parts that form a rough opening are the king stud, jack stud (I'd love to know the origin of these terms), header, sill and cripple. Each piece has a job to do. For example, the jack studs support the header, and the header is used to span the opening. And it should be noted that with a typical 8-foot ceiling, the standard 80-inch-high door fits neatly into a rough opening made with a double 2-by-12 header. With the header placed tightly against the underside of the double top plate, the rough opening measures about 82 inches high. While this isn't the most efficient use of material (the header is often much larger than required), it has become the norm because of its simplicity. |

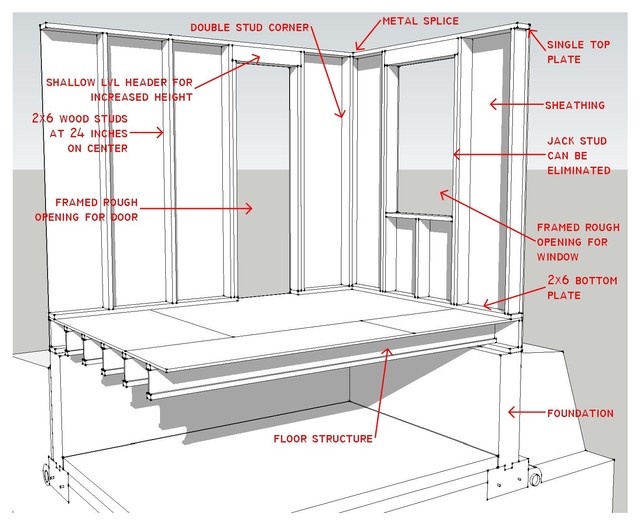

Optimized framing. Wood framing began when wood was abundant and inexpensive, and a home's thermal efficiency wasn't a consideration. As a result, traditional wood framing uses far more material than it needs to, and the typical 3.5-inch wall thickness doesn't allow for as much insulation as is required for a thermally efficient house.

More advanced framing techniques now use 2-by-6 wood studs in lieu of 2-by-4s, a single top plate and two studs in lieu of three stud corners. The benefits of using 2-by-6s include:

Optimized framing also uses headers that are sized as needed to span door and window openings. While this has the benefit of reducing material costs, it also achieves a distinct architectural look, as taller windows and doors can be had. Find unique and eco-friendly building supply at World Class Supply. |

No comments:

Post a Comment